New Showroom @ Sysmetric USA

Sysmetric USA is proud to announce the opening of the new showrooms at Sysmetric USA headquarters in Mooresville NC. Sysmetric plastic raw material handling and gravimetric CD blending systems are on display for both demonstration and training purposes.

January 2020

Visit the Sysmetric USA showroom for demonstrations of Sysmetric unique plastic raw material handling and blending systems.

Call us on (833) 215-6967 (Toll Free) and arrange a visit.

Lo último de Sysmetric:

Burbuja interna digital de enfriamiento (D-IBC) para la extrusión de película soplada.

10.10.2011

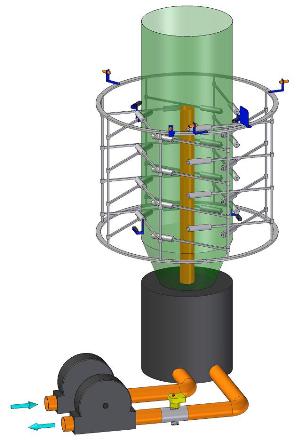

Digital Internal Bubble Cooling (D-IBC) for Blown Film Extrusion

The latest digital internal bubble cooling system developed by Sysmetric, has already seen over a year of successful activity. This system is part of the Sysmetric comprehensive line and profile control models.

The unique Sysmetric system employs 8 ultrasonic sensors (as opposed to 5 sensors to be found in most systems on the market), a Sysmetric designed dedicated “sensor-controller” circuit board, a new digital balancing valve developed by Sysmetric operated by a servo step motor and a unique control method called modeling.

All of the above features ensure both highly accurate width control and fast reaction times.

So Why Invest in this Type of Control System?

First and foremost, in order to reduce setup time and waste material created during product size changes without dependency on skilled operators thus saving money.

The high stability provided by the system allows changing production parameters such as increasing output whilst maintaining high production accuracy.

The meticulous checking of all of the system components that is carried out by the system during operation and the automatic back up of some of the components promises early detection of any faults before any damage can be caused and a reduction in valuable maintenance time.

Gili Gozani

![]()

Chief Engineer

Sysmetric

Range Plastics cosechar los beneficios de la línea de control

Range Plastics MD David Handley y jefe de producción Eddie Bezuidenhout, veterano del negocio de película soplada en el Cabo Occidental, están contentos con la calidad de la película PP está produciendo. La línea de coextrusión es capaz de producir tres capas de diferentes materiales y grosores. Los materiales sistema de manejo, incluyendo la dosificación

05.18.2011

Range Plastics’ MD Dave Handley and production manager Eddie Bezuidenhout, veteran of the blown film business in the Western Cape, report that they are happy with the quality of PP film being produced. The coex line is able to produce three layers of different materials and thicknesses. The materials handling system, including the dosing and blending units as well as the control system, was supplied by Sysmetric of Israel.

Plastics Today Noticia

Plásticos Today informa de que los sistemas de manejo de materiales SYSMETRIC están diseñados para un rendimiento preciso y un mantenimiento mínimo

09.09.2014

Plastics Today reports: Resin dosing, blending, and material handling systems engineered for accurate performance and minimal maintenance by Sysmetric (Israel) are available in the United States and Canada through CMD Corp. (Appleton, WI).

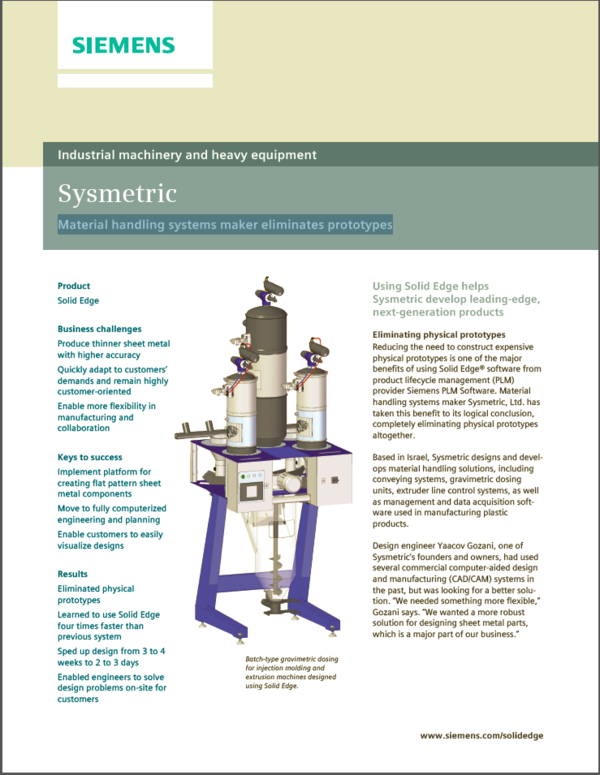

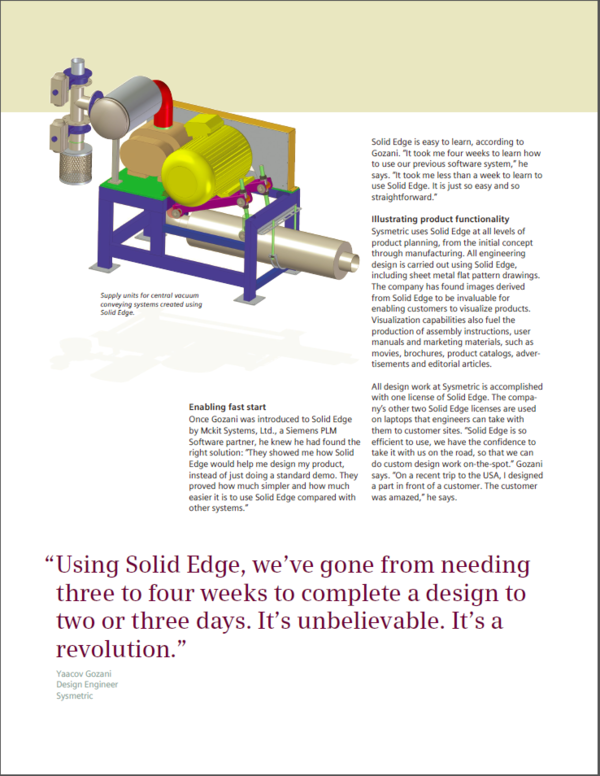

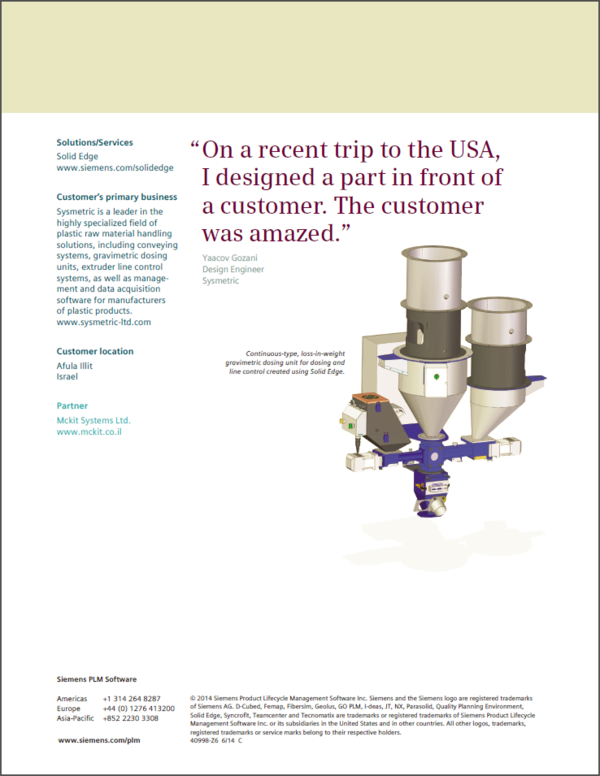

Sysmetric Case Study by Siemens

Reducing the need to construct expensive physical prototypes is one of the major benefits of using Solid Edge® software from product lifecycle management (PLM) provider Siemens PLM Software. Material handling systems maker Sysmetric, Ltd. has taken this benefit to its logical conclusion, completely eliminating physical prototypes altogether.

02.10.2014

Reducing the need to construct expensive physical prototypes is one of the major benefits of using Solid Edge® software from product lifecycle management (PLM) provider Siemens PLM Software. Material handling systems maker Sysmetric, Ltd. has taken this benefit to its logical conclusion, completely eliminating physical prototypes altogether.