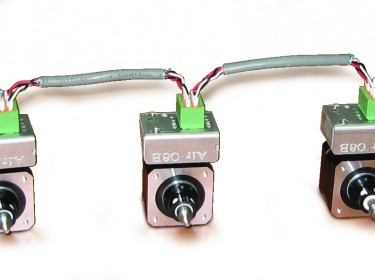

ABC ™ (Advanced Bubble Control) for fully automatic IBC and cage control. The latest digital ABC system ensure both highly accurate width control and fast reaction times.

Solutions

A blown film line pumps the molten plastic, at high pressure (300-600Bar), through a circular die that shapes the melt into a tube (the tube can be single layer or multilayer). As the tube is pulled from the die it is stretched and cooled to fix the product to the right size and thickness. The film stretching is longitudinal and lateral. Cooling is done by either water or air and can be external only or external and internal (IBC). On some lines the initial tube is then reheated and stretched again (double bubble). The tube is later collapsed into nip rolls.

Sysmetric provides superior solutions for the different production stages.

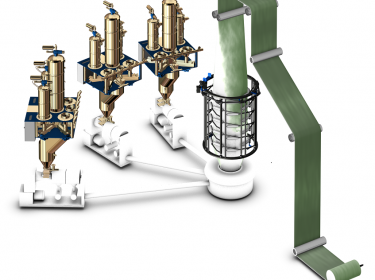

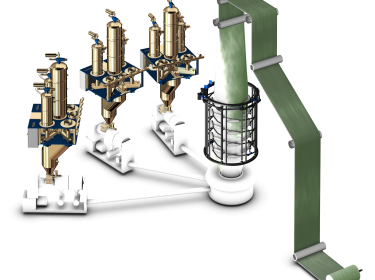

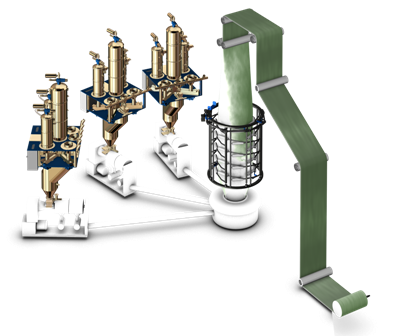

- Sysmetric has the best valued conveyingand dosing systems that feed each extruder with the accurate proportion of each ingredient.

- Sysmetric’s layer control adjusts each extruder capacity to produce the right layer thickness along with the line speed.

- Sysmetric’s ABCsystem accurately controls the Internal Bubble Cooling blowers, valve and the Calibrator Cage size. The ABC also sets the layer control to work in constant capacity during product changes so any maneuver is easily achieved.

- Sysmetric’s full line control, integrates layer control, width, IBC, temperature, tensions and other appliances present in the line that needs settings logging or control, under one unified system.

Sysmetric’s special APS (Automatic Pilot Start-up) line control technique, enables any operator to start-up even the most sophisticated line with maximum efficiency and minimum waste.

This is complemented by our computer software that monitors and control full product recipes and produces superior integration with the whole factory.